INTRODUCTION

1.Packaging and MPN Label Checking

Compare the label with original labels and official website information to determine its authenticity.

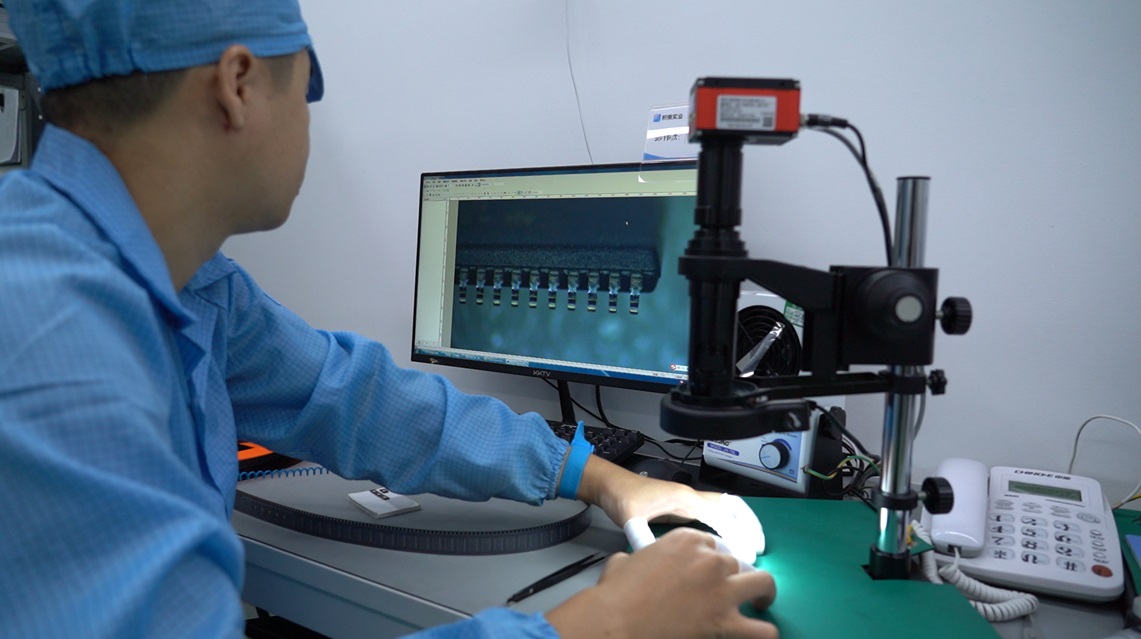

2.Physical Visual Inspection

Observe the sample's physical appearance, marking, packaging, and dimensions to ensure compliance with specifications, examing part's pin oxidization condition and copolarity.

3.Remarking & Resurfacing Test

Use chemical acetone or sharp tools to wipe or scrape the marking on the chip's front surface to determine if it has been remarked or refurbished.

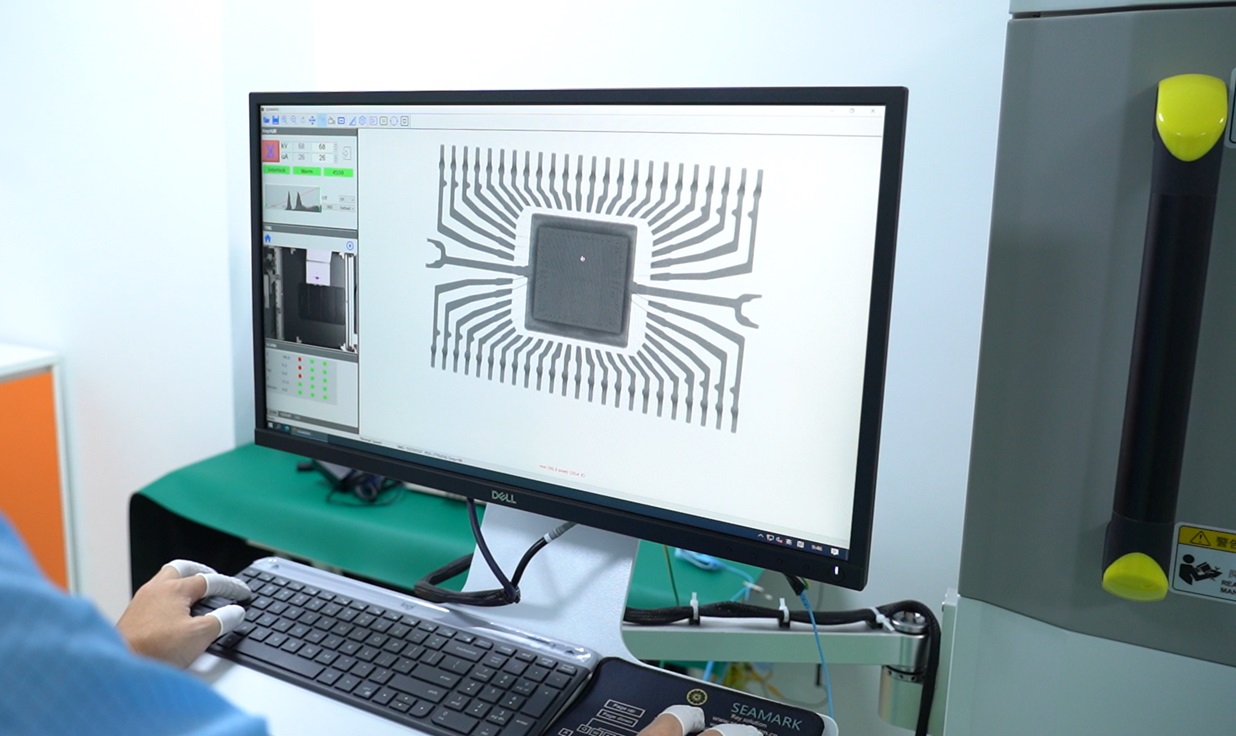

4.X-ray Testing

Inspect inside condition of chip to ensure they are authentic original parts, including frame, wafer size, pin pitch, gold wire, damage, and voids.

5.RoHS Testing

Examine whether the components meet RoHS standards.

6.Solderability Testing

Inspect the solderability of the component pins to ensure compliance with J-STD-002B standards.

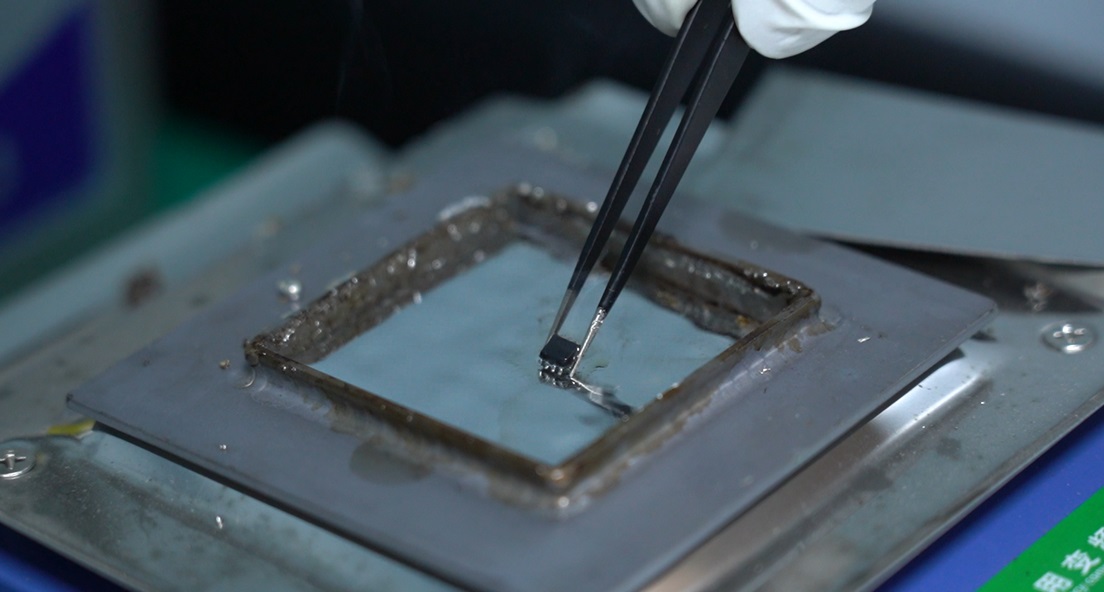

7.Decap Testing

Inspect chip wafer marking, logos, and other information.

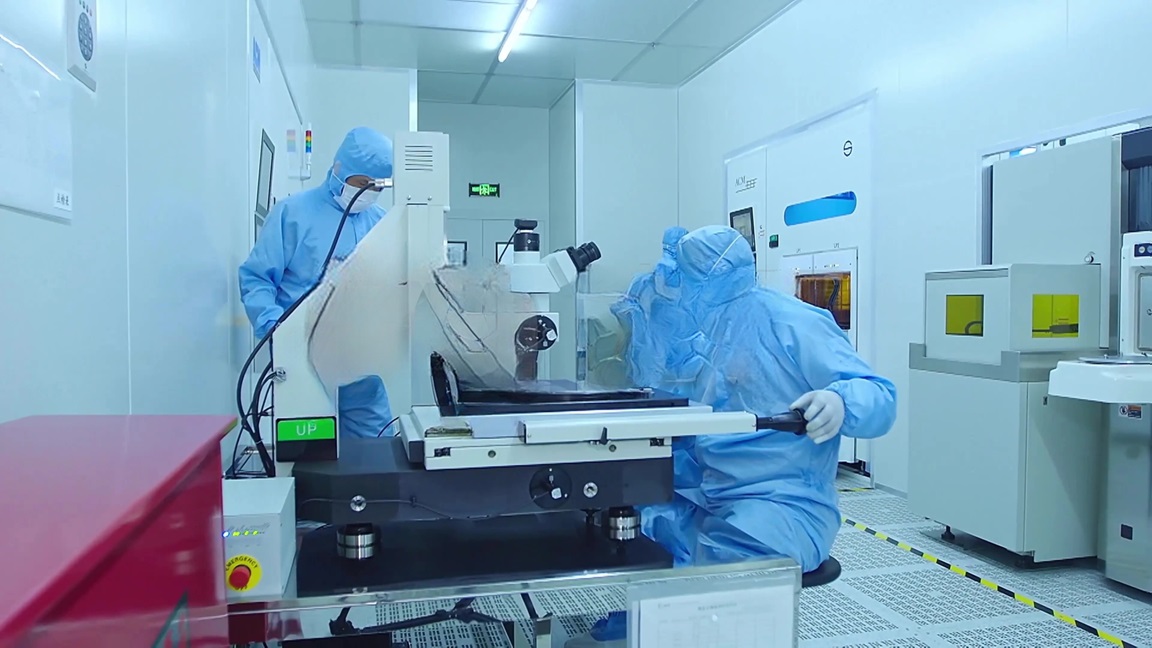

8.Electrical Performance Testing

Check component's electronical characteristics, such as resistance, capacitance, inductance, LED illumination, program testing, and so on.

9.Third-party Testing

Forward to the 3rd testing party according to customer requirements.

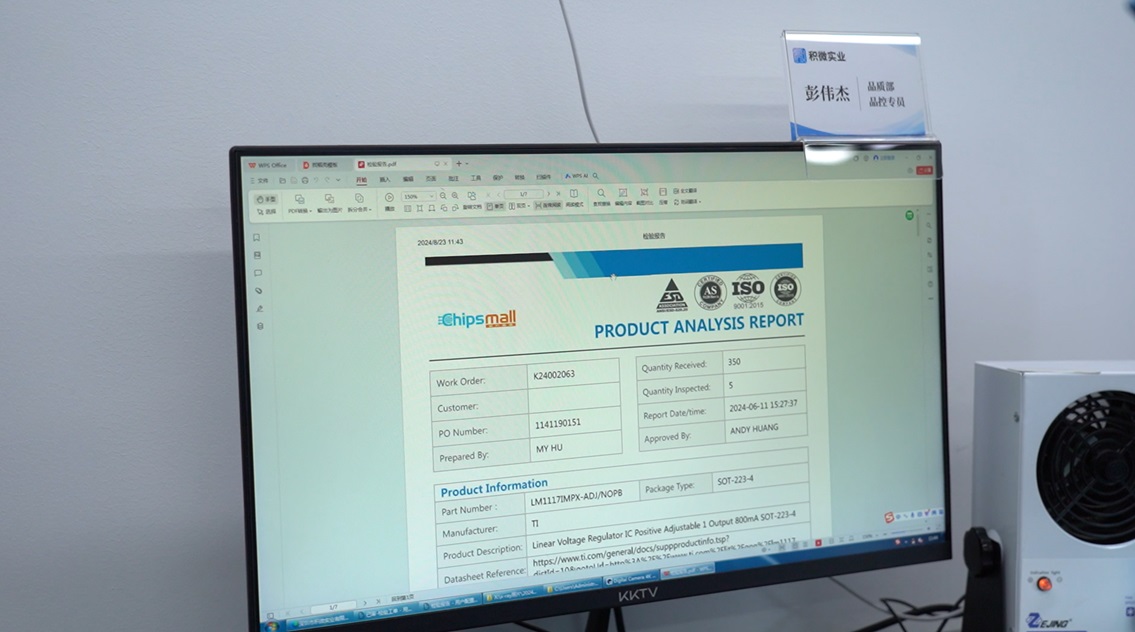

10.Generate a Test Report

Cross-check inspection and stamp for confirmation

Shenzhen Headquarter:

2/F,BLK. 405,Shangbu Pengji Industrial Area,Huaqiangbei,Futian,Shenzhen,China 518028

TEL.: +86-755-8981 8866

Hongkong Secretary Office:

RM 705, 7/F, Fa Yuen Commercial Building, NO.75-77, Fa Yuen Street, Kowloon, Hong Kong

TEL.:+852-6220 1873